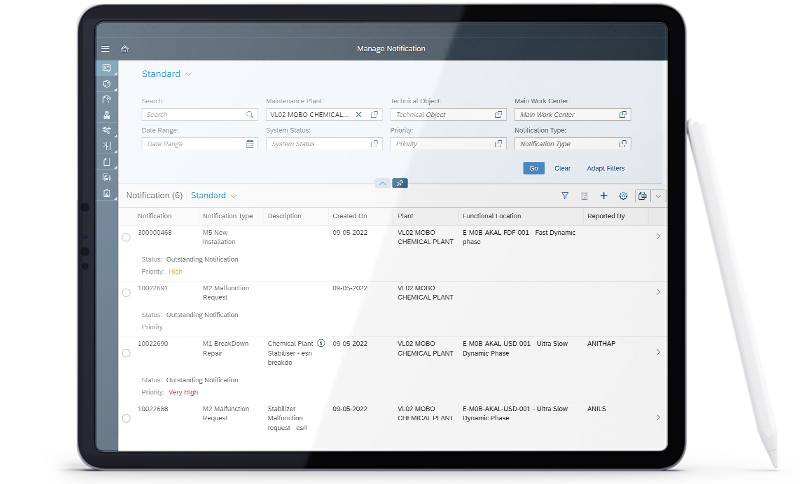

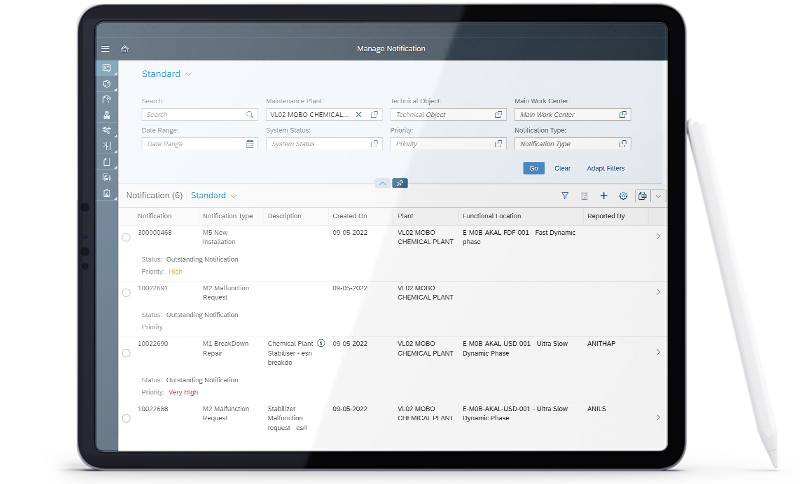

Notifications

A robust notification system empowers users to operate maintenance tasks more effectively with real-time alerts via email and WhatsApp. Notification templates can be preconfigured and triggered directly from anywhere.

These notifications can be managed, viewed, and edited from a centralized repository to provide a holistic view of the work orders being created to drive action. The intuitive on-screen maintenance alerts keep you on top of your maintenance.

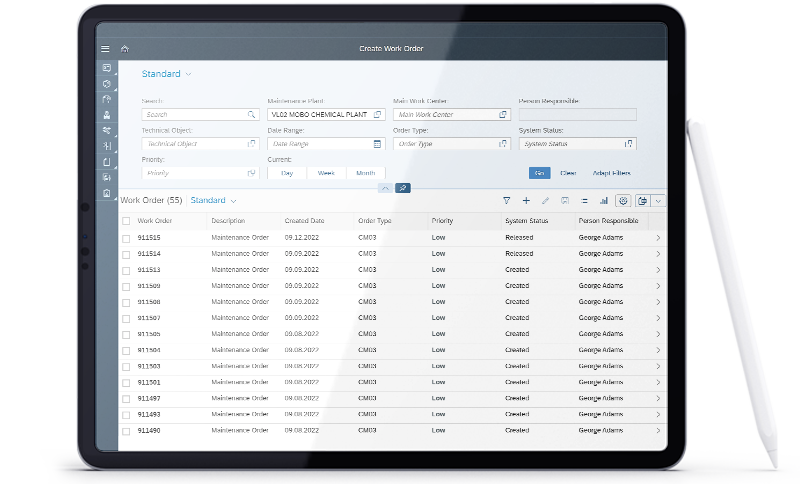

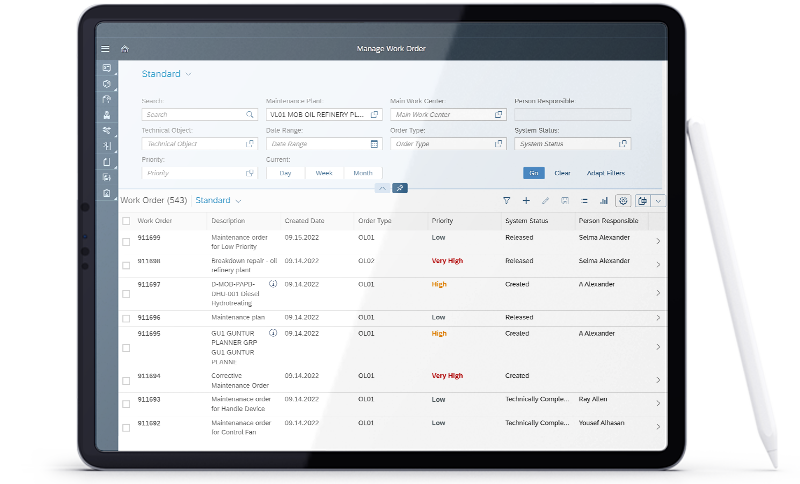

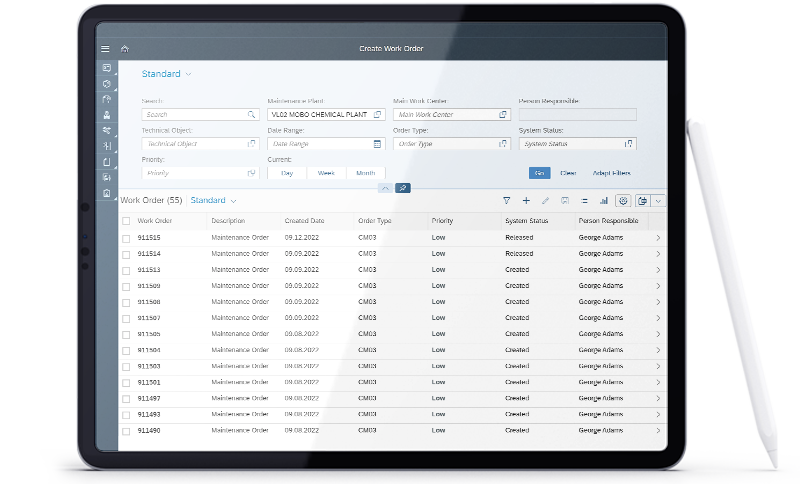

Work Orders

When it comes to Work Order Management, various degrees of outdated systems such as maintenance logs, spreadsheets, and alerting systems are in use.

Create maintenance work orders that contain all the information to initiate and manage maintenance work for an asset. Plant Maintenance 360’s easy-to-navigate app interface helps users track work order status and make faster decisions.

Users can also manage and perform work order activities from the intuitive task pane. You can use filters to search work order details based on the attributes of maintenance work orders. Track asset service history, event insights, service appointment, and all required line items.

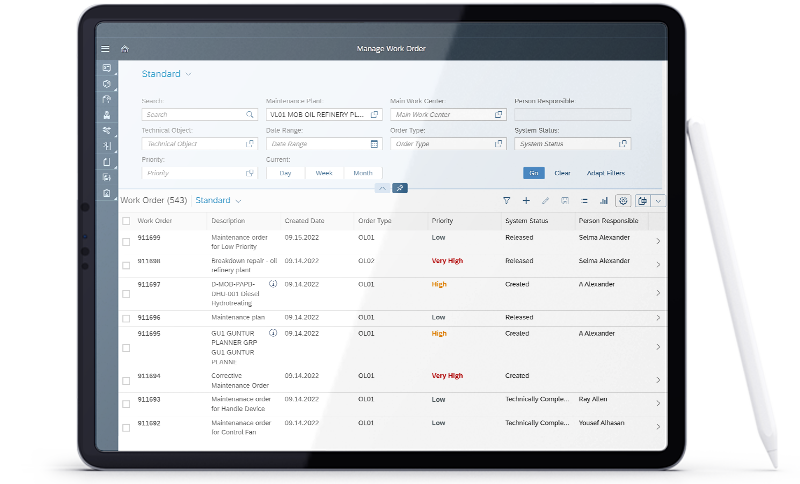

Assign Work Orders

Maintenance planners can locate the right technicians, directly assign resources to tasks, and revise resources at any specific time or location. This quick and simple way to schedule and assign work orders standardizes your maintenance workflow.

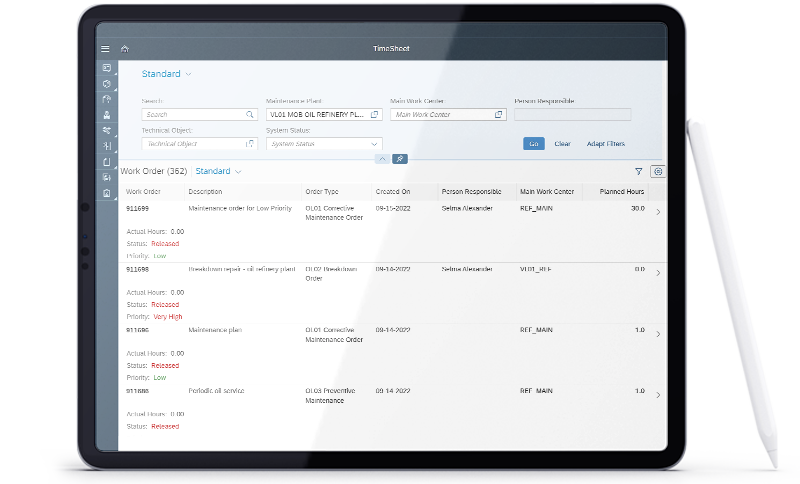

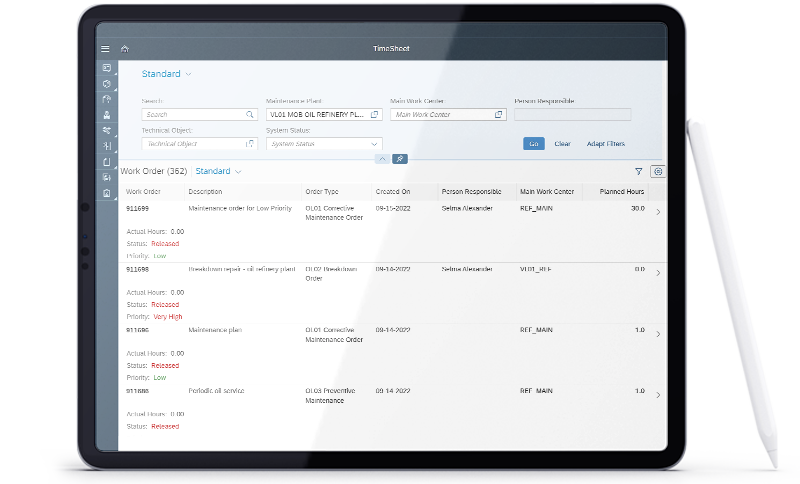

Time Entry

Efficiently run a complete time-entry against each work order accurately to calculate labor rate and costs. This optimized solution facilitates real-time reporting and accurate billable hours.

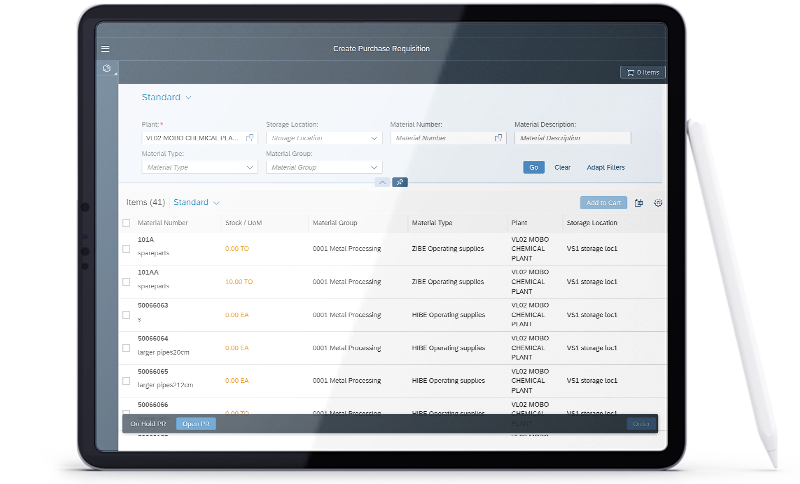

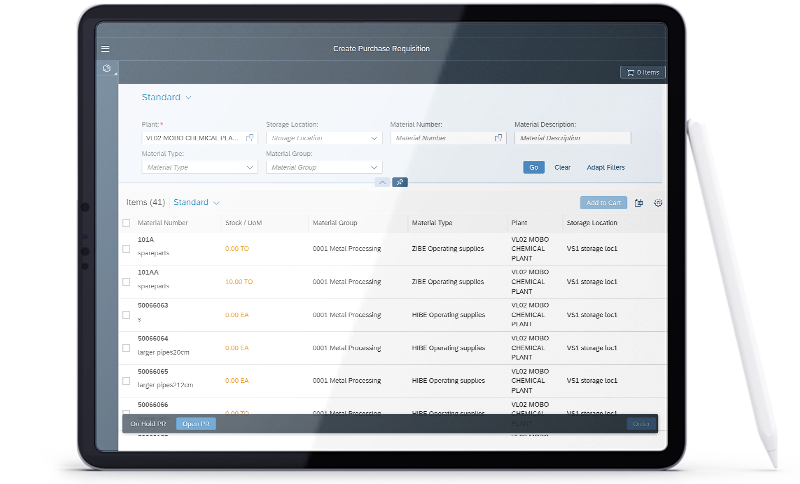

Create & Approve PR

Plan purchases of maintenance materials better and optimize organizational spending with streamlined PR creation. It optimizes procurement initiation and transaction flow by reducing the time and effort required to chase paperwork.

As Purchase Requisitions are routed to the authorized approver, the approver will be made aware of this requisition by a workflow message and he/she can view and approve. The approval console is designed in such a way so that the PR can be directed to multiple managers for approval.

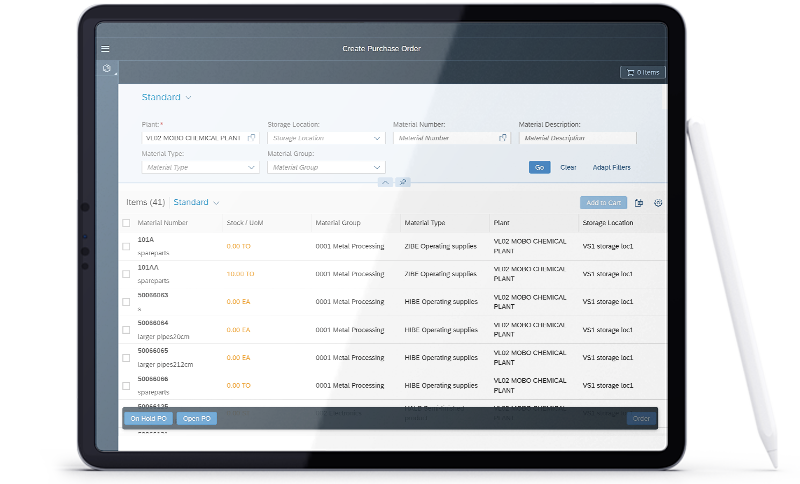

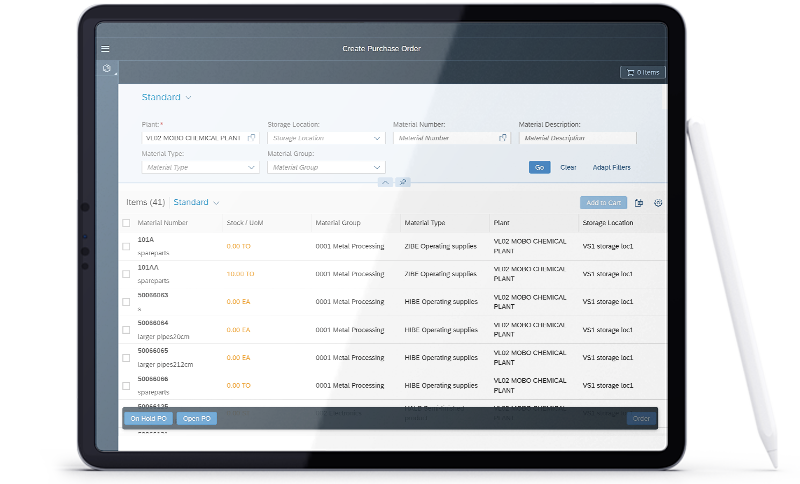

Create & Approve PO

Create instant purchase orders from approved purchase requisitions, verify purchase order content, and adhere to compliance efficiently. This makes it easier to track vendors, handle multiple purchases, inventory, and accounting.

The system sets up an efficient purchase order approval process that minimizes approval cycle time. Users can manage the complexity of approving different purchase categories and review how purchase order approval document travels throughout your organization.

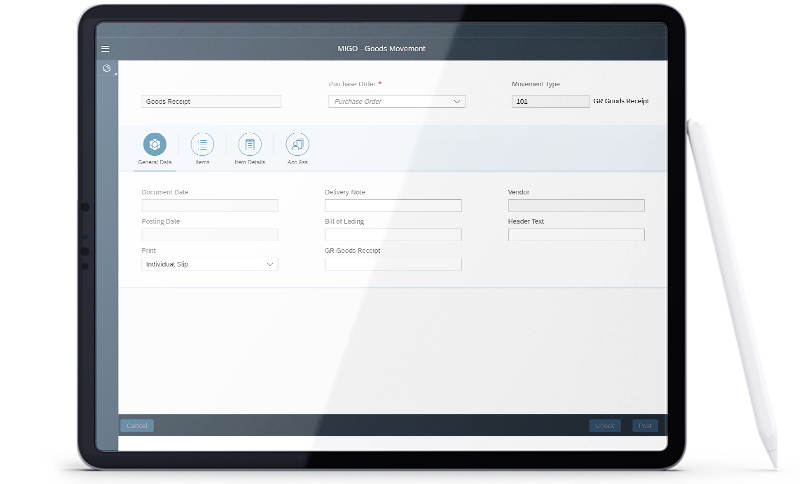

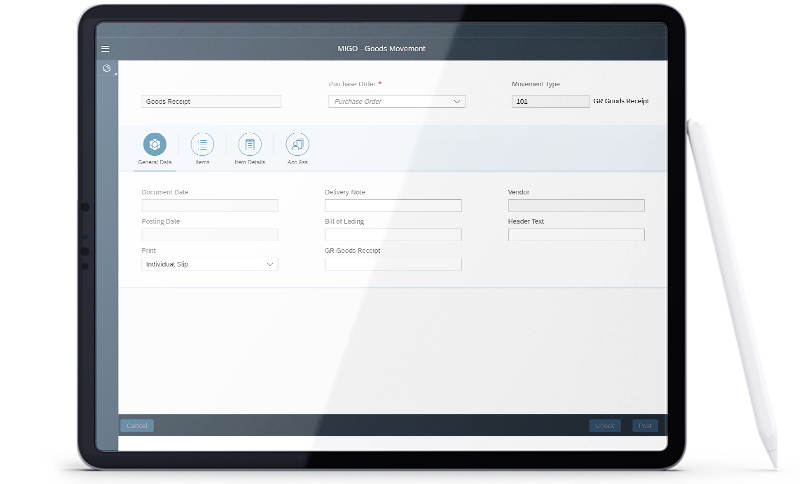

Goods Receipts

Create digital records of the inbound movement of goods or materials into the warehouse with the streamlined app. You can enter, view, and edit receipt of material – no matter the variety and quantity of the goods.